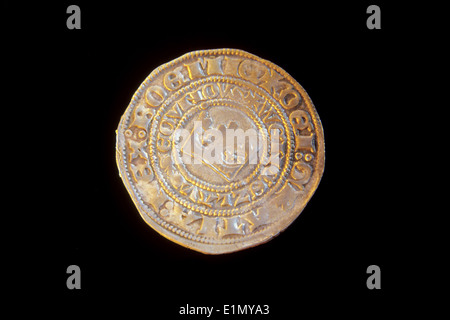

Creating a plaster mold or "maquette" that is based on a gold coin or medal design involves several steps to translate the two-dimensional design into a three-dimensional physical representation Initial Design Reference- The artist or designer uses the gold medal or coin design as a reference. The design could be a simple sketch created with a pencil, or it could be a digital image made by using graphic software. Other materials, such as clay or wax might be utilized.

Plaster Mixing- Plaster with water mix to create an even consistency. It is crucial that the mixture be smooth without lumps, and uniform in order to form an environment for mold.

Making the BaseA platform or base is made in which the maquette is created. The base could be an unfinished wooden surface or a piece of board.

The Maquette is created using the gold pattern as a model. This is the process of shaping plaster into a three-dimensional or relief image of the coin.

Detailing and Refinement - The artist creates details, refines the contours and ensures accuracy in proportions and design elements. This process requires precision and meticulous attention to the particulars.

Allowing time for drying and setting After the sculpting process has been completed, the plaster should be given time to set and dry. This will allow the maquette to set and retaining its shape.

Finishing the Maquette- After drying out, the surface is then smoothed to eliminate any bumps or rough spots.

Sealing and Preserving- To protect and preserve the maquette, and also to prepare it for further processes, such as scanning and molding, apply a sealant or protection layer to the surface.

The three-dimensional plaster maquette created is used to illustrate the gold design of a coin or medal. It acts as an exact reference for the next stage of production. It is possible to use it to digitize the image or to create molds for mass production. Artists can utilize it as a reference to conceptualize and improve their designs prior to the finalization of their design. See the top Czechoslovakia gold coins plaster molds website examples. including gold price jm bullion, 1 10 ounce gold coin, gold buffalo, sacagawea gold dollar, gold silver shops near me, 1 oz gold bars, coin 1, canadian gold maple leaf, olympic games gold medal, gold bars price and more.

What Is The Process By Which The Janvier Machine Transfer Gold Coins Or Medals From Master Hubs To The Working Hub?

The Janvier machine, sometimes known as a pantograph or reducing device, is a specialized machine used in the minting process to transfer an image of a medal or coin from a master hub into an operational hub. Here's a quick overview of this Master Hub Creation.

The master hub, also known as the original mold or die, is the first mold or die which contains the exact design and layout of the coin. To ensure its accuracy the hub is usually made using CNC manufacturing and other precise methods.

Janvier Machine - Setup

The Janvier machine consists of a stylus that traces the pattern on the hub master, and a cutting tool that copies this design to the hub in operation.

The master hub is securely placed on the Janvier machine, serving as a template upon where the design will be transferred.

Tracing the design-

The Janvier machine's stylus records the profile of the design while it travels along the hub's surface. When the stylus is moved on the surface of master hub it tracks its contours.

Reduce the Design

Simultaneously on the Janvier the cutting tool replicates the traced designs onto the machine's hub, which is usually constructed from steel, a soft metal or nickel.

The cutting device reduces or copies the design onto the hub of the working wheel, but at a lower scale or size in comparison to the hub that is the master hub. This decrease in size is critical in the making of medals and coins allowing them to be struck at the right dimensions.

Precision and Accuracy

Janvier is a high-precision machine that guarantees a precise transfer of design from the master hub to the working hub. It faithfully reproduces even the most intricate details and contours.

Quality Control -

Inspections and quality checks are conducted to confirm that the design used is compatible with the specifications and precision required for the striking process.

Further Processing-

The Janvier machine's working hub is used to create coins or medals. It is used as a mold or die that is used to make numerous blanks for coins or medals with the transfer design.

The Janvier machine plays an important part in the production process by allowing the exact replication and reduction of intricate designs on medals and coins from a working hub to a master hub. The working hubs can be utilized to mass produce medals or coins using the strike process. See the top rated janvier processing Prague Mint gold coins site info. including buying silver, 2000 p gold dollar, gold medal of olympic, michael phelps medal, 2000 p gold dollar, today's 1 oz gold coin price, price of gold 1 oz today, golden and silver, 1 oz gold buffalo coin, 1 oz gold and more.

Why And How Are Some Surfaces, Such As The Matte Or Textured Surfaces, Created Using Sandblasting?

This technique is used to make matte or textured surfaces on gold-plated coins and medals. The technique is employed to achieve a number of different reasons.

Surface preparation - The coin or the medal is put inside a cabinet, chamber or nozzle that is connected to an air compressor. The chamber is usually covered to protect the abrasive material used in the process.

Abrasive Material Select- Abrasive particles such as glass beads, aluminum oxide silica carbide and sand are launched at high speed on the surface.

High-Pressure Propeller - The abrasive particle is launched onto surfaces using compressed air. The finish or texture will be determined by the force and speed with which the particles hit the surface.

Texture Creation: The force of the abrasive particles on the surface results in a matted or textured look by changing the topography of the surface. This process is able to create a specific roughness in specific areas or produce a consistent texture throughout all surfaces.

Controlled application- Sandblasting is controlled by the intensity duration, duration and angle of application. This allows for a variety of types of finishes and textures. Different abrasives and pressure levels result in different outcomes.

Sandblasting is used for a variety of reasons.

Texture variations- Sandblasting permits the creation of various types of textures and surfaces, such as mattes, frosted or rough surfaces. This creates an aesthetic appeal and adds unique characteristics to the coins or the medals.

Aesthetic Enhancement- Sandblasting alters surface appearance. It diffuses light reflections and reduces shine. This enhances the visual appeal of a coin or a medal. Matte finishes, for example can highlight certain design elements by reducing reflections and glare.

Anti-Glare properties- Matte or textured surfaces produced through Sandblasting can decrease reflections and glare, making the coins or medals more visually appealing and easier to view without interference from light.

Sandblasting Produces Contrasting Design Elements - Sandblasting creates a contrast between the polished and the texture areas on the medal or coin, highlighting certain design features or adding visual depth.

Sandblasting can be customized to allow for artistic expression, and allows coins or medals to be designed with different textures or finishes unique to the style.

Sandblasting, an incredibly versatile technique employed to create different textures and surface finishes on coins or medals. It enhances the aesthetic appeal, visual appeal as well as overall design. Follow the top sandblasting Prague Mint gold coins more info. including coin gold silver, buy silver & gold, cost of 1 oz of gold, bullion price of silver, 1 10 american gold eagle, gold coin prices, gold coins coin, 10 dollar gold coin, 1 0z gold price, buy gold bars and more.

What Is The Process For Having Gold Coins And Medals Checked For Quality To Make Sure They Are In Compliance With The Specifications??

These checks are carried out to ensure the coins or medals are in compliance with specifications and that they have a precise surface. There are several steps in these tests.

Certified inspectors examine every medal or coin to identify any surface defects, blemishes, or imperfections. They look for marks, scratches and irregularities that could affect the appearance of the coin or its value.

Weight and Dimensions-

Weighing and measuring each coin or medal ensures that it satisfies the specified weights and diameters, thicknesses, and overall dimensions as per the design specifications. Any deviations from the design specifications could suggest an issue with the quality.

Metal Purity, Composition and composition

Quality checks are used to determine the gold content or purity of medals or coins employing different methods, such as chemical or XRF analyses. This ensures they meet the required gold content and quality standards.

Edge InspectionEdge Inspection

The inspectors examine the edges of coins and medals to ensure uniformity, any irregularities (if they are present) and reeding. Edges are an important element to be incorporated into security features as well as other design elements.

Strike quality

It is essential to determine the quality of each piece, such as the sharpness and clarity of the design, relief and overall look. This will help ensure that each piece is consistent.

Errors in minting and proofing

To determine if there are flaws, imperfections, or other flaws A thorough examination is performed on proofs that are specially crafted coins.

Packaging and presentation

Packaging and presentation are also subject to quality checks. This ensures that coins and medals are kept in a safe manner or displayed in case or holders, without any damage or contamination.

Random and Sampling Checks

Random checks or random sampling are conducted on the batches to ensure that high standards of quality are consistently met throughout the entire process of minting.

Documentation and compliance

Documentation is kept of all quality checks in order to confirm compliance with the regulations, standards and certification requirements. These records are used to prove the authenticity of the coin and its quality.

Reject non-conforming items

The high quality of coins and medals is maintained by refusing to accept or reprocessing any that are not in compliance with these standards.

Mints and certification authorities conduct these quality checks to ensure gold coins and medals meet required standards of quality, accuracy, purity and design. They also assure collectors, consumers and investors that the coins and medals are authentic and of high-quality. Check out the top Prague Mint gold coin quality control blog tips. including silver double eagle, st gaudens double eagle, mexican gold coins, 1oz gold, gold eagle coin, 2000 dollar coin, gold eagle price, gold angel coin, purchase gold coins, silver price in dollar and more.